* – This article has been archived and is no longer updated by our editorial team –

What makes Solex Thermal Science unique is its full service approach. Providing experienced field application engineers to compliment the proprietary thermal modelling capabilities, bulk solids engineering and project delivery staff. Solex’s approach not only provides customers a custom designed solution and field service support to optimize their unique process, but also lowers operating and maintenance costs as it contributes to reduced emissions and energy efficiency gains.

Recommended: Meazon Leverages New And Existing IoT Tech To Provide Cost-Effective Energy Management Solutions

Recommended: Meazon Leverages New And Existing IoT Tech To Provide Cost-Effective Energy Management Solutions

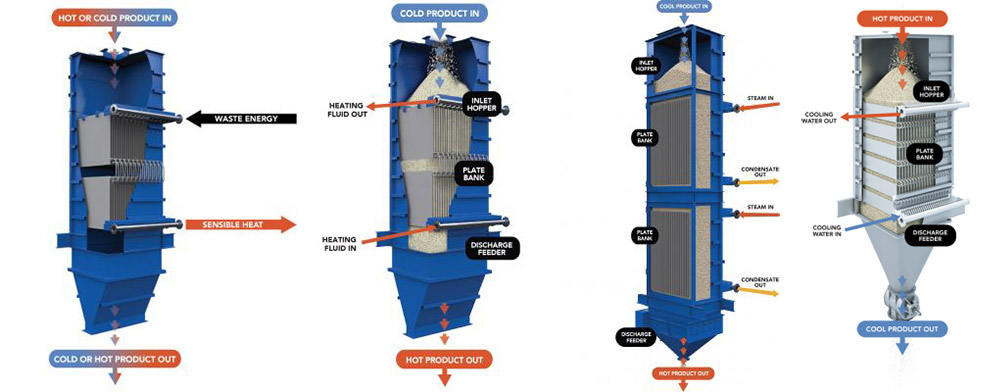

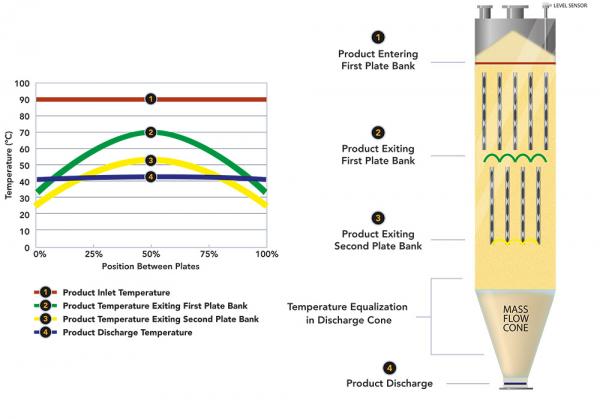

Solex’s patented and patent pending heat exchangers provide predictable and uniform temperatures while using up to 90% less energy. The indirect plate technology allows customers to capture and use low-grade heat from elsewhere in their facility for heating bulk solids. The individually removable plate design offers superior performance to other designs and allows ease of maintenance.

The company was recently honoured at the Alberta Exports awards, where it received the Exporter of the Year Award as well as the Clean Technology Award. The Alberta Exports awards acknowledged Solex’s achievements in both pioneering ‘clean’ technology, and international business. ”We’re privileged to accept these two awards: while we’re focused on reducing the environmental footprint of our customers, we also strive to grow Alberta’s economy through innovation and employment of up-and-comers.” Paul Crawford, Solex’s President, explains.

Recommended: Livible Expands To Boston And Beats The Competition In Full-Service Storage

Recommended: Livible Expands To Boston And Beats The Competition In Full-Service Storage

Solex is working in new applications such as pharmaceuticals, coffee drying and foundry sand conditioning but also in alternative energy. The research and development team are currently working with concentrating solar power companies on energy capture, storage and recovery projects, as an alternative to conventional energy storage. And working with the automotive industry to use heat exchangers to capture airborne solvents during the coating and painting process. The technology can be potentially used with any type of application that would benefit from the capture of gases through adsorption.