ClearEdge3D is a company focused on using computer vision as a tool to dramatically enhance the productivity of working with reality capture data for AECO workflows. Below is our recent interview with Kelly Cone, V.P. of Industry Strategy at ClearEdge3D:

Q: Could you provide our readers with a brief introduction to ClearEdge3D?

A: So, I always like to describe ClearEdge3D as being a company focused on using computer vision as a tool to dramatically enhance the productivity of working with reality capture data for AECO workflows. Essentially, we try and take tedious or repetitive tasks and apply our collective decades of experience with writing computer vision algorithms to take a first pass at completing those tasks and then let you review the results and add finishing touches on top of that.

Q: You’ve recently launched Verity Photo, fulfilling 2017 BIMtrace acquisition promise; could you tell us something more?

A: Verity photo basically streamlines the process of taking photographs and comparing them to 3D coordination models in Navisworks. This isn’t something easily done on the desktop right now without Verity photo. You basically end up opening an image and a model side by side and visually comparing them or opening the model on the site and visually comparing what is installed against what isn’t. But, this isn’t something you can extract measurements from, or precisely match a perspective to facilitate an accurate comparison… There are some interesting AR approaches on the market that aim to solve this comparison in the field, but frequently the people in the field aren’t comfortable with that technology or its current limitations, there are also safety concerns and other usability issues that hinder use. So, instead, we rely on just a simple camera on an iOS device and put only the capture and review in the hands of the field. So, as long as they’re comfortable taking a photo, they can use Verity Photo. Once the app has captured a pre-located image, that gets sent back to the office and the VDC staff takes over in Navis. Aligning an image precisely to the model is then as simple as picking similar edges in the image and the model. Once edges are identified, the photo is aligned and overlaid in 3D space allowing some really interesting workflows… We can vary the transparency of the photo overlay to aid the visual comparison, markups can also be added, including basic measurements! Those can be sent back to the field or uploaded to ProCore or BIM 360 Field for tracking the issues through to resolution.

Recommended: Guaranteed Removals Vs. Profile Defenders

Recommended: Guaranteed Removals Vs. Profile Defenders

Q: Can you give us insights into your products?

A: Of course! We basically have two product lines currently…

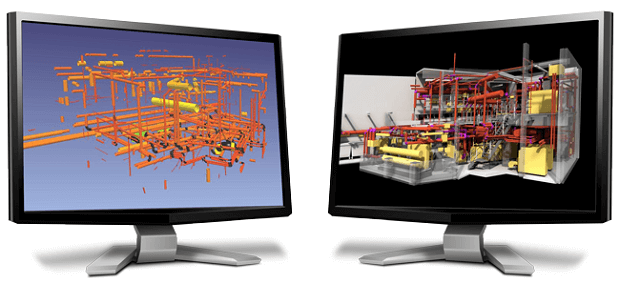

1. EdgeWise – Our various EdgeWise products are focused on Scan-to-BIM or Scan to CAD workflows…

- Pipe / Conduit / Round Duct – Our software can automatically recognize cylinders in laser scan data and extract the geometry into piping, conduit, or duct systems. We have tools to auto-connect systems, simplify the accurate as-built to a more as-intended state, and to standardize the systems based on specs. This auto-recognition and auto-completion technology can complete between 60% and 90% of these systems on typical jobs with typical quality scans. From there the user takes over reviewing the results and adding additional components.

- Rectangular Duct – Our rectangular duct tool is used to extract straight rectangular duct from scan data using our auto-completion technology to connect these segments into a connected system. This cuts the time to make accurate duct models from scan data by at least 50%.

- Walls – Our algorithms automatically detect planes in the scan data and uses these as a basis for identifying walls. Once levels are identified by the user, we can automatically detect walls from the extracted planes and populate the model with wall geometry. For interior spaces with lots of partitions, we can easily extract 80% of the partitions with typical scan data.

- Structure – For structure we leverage the patterned nature of structural designs to automate the placement of additional components based on initial extractions of types of components by the user. For highly repetitive structures, this system can reduce the man hours required to model from the scan by up to 80%.

- Of course, all that is useless if the data is stuck in our applications. We can export the extracted geometry to STEP, COE and some other formats. More importantly, we have plugins for Plant3D, PDMS, and Revit to use our project files to re-draw the geometry natively in those applications. This gives you fully editable elements in these BIM systems so you can use them to design modifications and additions to these existing systems without any compromises.

2. Verity – Our Verity product line is focused on quality control and assurance workflows…

- Verity – Our Verity software compares 3D model geometry to scan data in order to check the conformance of the models to the scan data. This can be used to validate that site installation has gone to plan, or to make sure that Scan-to-BIM geometry is within a required tolerance of the scan data. The technology uses our computer vision algorithms to both check the installation or modeling status of the elements, and then fits a duplicate copy of the geometry to the point cloud data providing a large number of automated measurements of the difference between the as-intended and the as-built location. Once this is done, you review the results, make any adjustments for incomplete or poorly matching data, and then produce variance reports in HTML, or export the points and as-build geometry for consumption in Navisworks or the authoring applications. These can be uploaded to BIMTrack, ProCore, or BIM 360 Field for tracking through to resolution.

- Rithm for Navisworks – Rithm builds upon the capabilities of Verity with workflow specific analysis and reporting for floor flatness, beam deflection, and accessibility requirements. Rithm leverages industry standard testing methodologies to provide industry compliant reports

- Verity Photo – Described above…

Q: Why is now the time for a technology solution like ClearEdge3D?

A: Well, we’d argue that years ago was “the time”, but I suppose we’re biased. The short version is that barriers for adoption are coming down across the board for using laser scan data on AECO projects… The prices of the hardware and software are decreasing which naturally expands the types of projects and workflows it is cost-effective on. Second, the software and hardware are getting easier to use and thus easier to train making internal implementations of these tools cheaper allowing faster ROI from the implementation itself. Third, the number of uses for this data is increasing rapidly. Laser scans aren’t just for Scan-to-BIM anymore. There are great tools that can support using this data for QA/QC workflows, Coordination, Standard testing, Progress tracking, etc…

So, we are entering a period of time where Laser Scanning isn’t a bleeding edge solution, and is in the process of moving from a tool for early adopters to a viable tool for most projects and most companies with the willingness to experiment. So, while it isn’t yet to the point where “everybody” is doing it, this is the time to get involved and start using the tools so you can capitalize on the differentiation it can buy for your company. So, I suppose, now is the time…

Recommended: Fullscreen Helps You To Grow, Engage And Monetize Your Social Audiences

Recommended: Fullscreen Helps You To Grow, Engage And Monetize Your Social Audiences

Q: What are your plans for the future?

A: Well, I can’t tell you too much of that without an NDA – which would more or less defeat the purpose. In terms of what I can share – it won’t be too surprising for anyone already using these tools. We have been watching the growth in mobile indoor mapping systems closely and feel like that too is staring to take off finally – so we’re making changes to our software to work better with that kind of data. This will in turn relax requirements on terrestrial data which I know our existing and future customers will greatly appreciate. We’re also actively working on ways to further reduce the barrier to adoption of these kinds of tools whether that is by ease of use or by additional workflows we can enable with this data. We don’t make hardware ourselves, so we’ll have to leave equipment costs to the manufacturers – but we expect to see the long-term trend of capabilities coming down in costs – which just means more people will need tools like ours to make better and more efficient use of that data!